From Bioblast

|

O2k-chamber |

MitoPedia O2k and high-resolution respirometry:

O2k-Open Support

Description

O2k-Chamber: Duran® glass polished, with standard operation volumes (V) of 2.0 mL or 0.5 mL (small chamber volume in the O2k-sV-Module, 12 mm inner diameter). The optical properties of Duran® allow application of fluorometric sensors (Duran® optical properties).

Reference: Product details and purchase information - O2k-Chamber (2.0 mL), O2k-Chamber sV (0.5 mL)

O2k-chamber: paradigm shift in HRR from mimimum to optimum volume

- Small experimental chamber volumes of 20-50 µL generate problems rather than providing resolution with small amounts of tissue samples, low numbers of cultured cells or few isolated mitochondria. The surface to volume ratio increases with decreasing chamber volume, thus various boundary effects entail larger errors at smaller volume, in particular oxygen diffusion. While the rate of oxygen depletion per unit amount of sample increases linearly with decreasing chamber volume, side effects may increase to a larger degree. Then, sensitivity is lost with decreasing chamber size. We recommend a minimum chamber volume of 0.5 mL of the O2k-sV-Module or 2.0 mL for the operational volume of the O2k-chamber supporting all O2k-Modules.

- 1. Minimization of chamber volume represents a past paradigm, aming at high rates of oxygen consumption per volume. The advantage appears to be obvious, whereas the drawbacks are frequently overlooked — see below.

- 2. Advancements of electronics, data acquisition and analysis, polarographic oxygen sensor specifications and chamber design made possible a superior approach, allowing for respirometric measurements at high dilution, as reviewed by Gnaiger E (2001). In specifically designed mitochondrial respiration media, respiration is stable at high dilution, multiple substrate/inhibitor titrations are possible without oxygen depletion, and a low-oxygen regime may be chosen to prevent elevation of oxidative stress at air-level oxygen saturation. In contrast, micro-chambers are characterized by a high surface-to-volume ratio which hinders optimum stirring, increases unfavourable surface effects and oxygen-backdiffusion, and poses problems with accurate titrations and dilution effects of the sample. These potential - and mostly hidden - artefacts are avoided in high-resolution respirometry (HRR), using glass chambers, titanium stoppers, and avoiding teflon-coated stirrers or perspex (yielding high back-diffusion of oxygen).

- Assume you have 0.1 mg mitochondrial protein for a respirometric assay. Approach (1) would lead you to search for a 100 µL volume respirometer, to maintain a classical 1 mg/mL protein concentration. In contrast, HRR allows for dilution of mitochondria to 0.02 mg/mL protein concentration. Dilution of 0.1 mg mitochondrial protein in a 2-mL chamber yields an optimum concentration for multiple substrate/inhibitor titrations and kinetic measurements. The high-resolution approach of the Oroboros O2k offers the unique advantages of a versatile and ready-to-use system for studies in mitochondrial physiology and pathology.

Compare 0.5 mL and 2.0 mL O2k-chambers

| experimental volume V | 0.5 mL | 2.0 mL |

|---|---|---|

| O2k-Manual | MiPNet24.14 O2k-sV-Module manual | MiPNet22.11 O2k-FluoRespirometer manual |

| O2k-Chamber | O2k-Chamber sV - exclusively for HRR: • O2 consumption | For HRR • O2 consumption, fluorespirometry • H2O2, • mt-membrane potential • ATP production • Ca2+, TPP+-Module • mt-membrane potential, pH-Module, NO, Q-Module, NADH-Module, PB-Module |

| inner diameter of glass cylinder | 12 mm | 16 mm |

| outer diameter of glass cylinder | 24 mm | 24 mm |

| thickness of glass wall | 6 mm | 4 mm |

| stirrer bar | Stirrer-Bar sV\white PVDF\11.5x6.2 mm | Stirrer-Bar\white PVDF\15x6 mm Stirrer-Bar\black PVDF\15×6 mm |

| stopper | Stopper sV\black PEEK\conical Shaft\central Port - for HRR | Stopper\black PEEK\conical Shaft\central Port - for HRR |

| O-ring | O-ring sV\Viton\9.5x1 mm | O-ring\Viton\12.5x1 mm |

| volume-calibration ring A/B | Volume-Calibration Ring sV | Volume-Calibration Ring |

| stopper capillary diameter | 1.00 mm | 1.30 mm |

| stopper capillary crossectional area | 0.79 mm2 | 1.33 mm2 |

| stopper capillary length | 50.64 mm | 48.86 mm |

| stopper capillary volume | 39.8 µL | 64.9 µL |

| stopper capillary dead volume Vstc including small meniscus | 0.04 mL | 0.07 mL |

| volume V´ for volume calibration | 0.54 mL | 2.07 mL |

| stopper spacer | Stopper-Spacer | |

| O2k-chamber holder | O2k-Chamber Holder sV | O2k-Chamber Holder |

| OroboPOS-Holder | OroboPOS-Holder sV | OroboPOS-Holder |

Cleaning the O2k-chamber

- There are different kinds of contamination that can accumulate in the measuring chamber of the O2k and may cause problems. All of them have to be treated in different ways:

- Biological contamination: The ideal counter agent is 70 % ethanol with 30 % water (NOT 100 % ethanol). If this does not help, the biological contamination may be embedded in a protein contamination and the glass chamber should be disassembled and cleaned as described below.

- Protein contamination and other macroscopic deposits: After long-term use, a whitish deposit can form on the glass walls of the O2k-Chamber. Additionally, small glass splinters (difficult to see) may stick to such deposits. A sign of this is a jumping or stuck stirrer bar. In this case, remove the glass chamber from the O2k. Immerse the O2k-Chamber (without the stirrer and without stopper) into a glass beaker with 10 mol/L hydrochloric acid (HCl) under a hood for at least an overnight period. The glass beaker should be covered to avoid evaporation of the HCl solution.

- Contamination by hydrophobic inhibitors: The ideal counter agent for this case is pure ethanol.

- Carry-over of inhibitors or uncouplers: It is recommended to wash the O2k-chambers with cells, thom or imt. Specific inhibitors bind to the mitochondria and are thus removed with high affinity to the mitochondria. Excess amounts of experimental samples of cells, tissue homogenate are isolated mitochondria can be used after storage at -20 °C for washing the chambers. If available, living cells are preferred. Without disassembling the O2k, fill the O2k-chambers to the rim of the Chamber-holder with the suspension, insert the stoppers loosely (sliding down without engaging the O-ring at the glass chamber), and stirr for at least 30 min.

- There are different kinds of contamination that can accumulate in the measuring chamber of the O2k and may cause problems. All of them have to be treated in different ways:

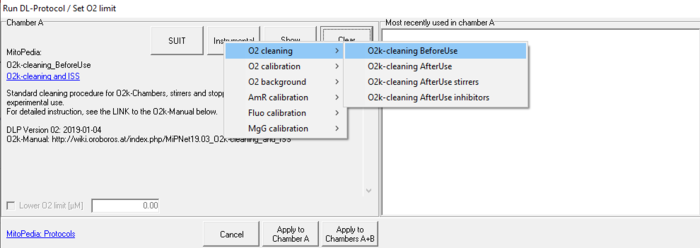

- DL-Protocols (DLP) should be used for cleaning the O2k-chambers, stirrers and stoppers before and after experimental use. A full list of Instrumental DL-Protocols for cleaning is displayed in the 'Protocols' menu ('Run DL-Protocol / Set O2 limit' window). See [Instrumental:_Browse_DL-Protocols_and_templates Browse Instrumental DL-Protocols for cleaning]

- » Further details: O2k-cleaning and ISS

- Inhibitors may be introduced accidentally, one example being 70 % ethanol used in hospital settings containing antiseptics. Such inhibitors may accumulate in plastic parts and inhibit subsequent experiments.

- » Further details: Discussion.

- In specific cases (e.g. working with bacteria), the chamber can be sterilized with 3% formaldehyde for 10 min before the experiment, followed by three washing steps with ddH2O.(https://wiki.oroboros.at/index.php/Steininger_2002_J_Antimicrob_Chemother)

O2k-chamber assembly - possible problems

- A properly assembled O2k-chamber can remain in the O2k for extended periods of time.

- It is recommended to disassemble, clean and reassemble the O2k-glass chamber at least every 1 - 2 years, to avoid the chamber from getting stuck, to clean the glass properly, and to detect any possible damages.

- After assembly, medium is leaking out of the chamber

- Siphon off medium and disassemble the chamber.

- Check for apparent damages of the glass chamber, the POS seal tip and O-rings on chamber holders and stoppers. If any damage is visible, replace the part.

- Reassemble the chamber and proceed with an QC1: Oxygen sensor test.

- Oxygen leak of the chamber (strongly negative intercept in the instrumental background test)

- Unstable O2 signal

- Unexpected high or low O2 signal

- The possible contribution of chamber assembly is checked by removing the OroboPOS from the chamber and observing, if the signal changes to the expected values.

- If the O2k signal responds as expected, reassemble the O2k-chamber and proceed with an QC1: Oxygen sensor test.

Leaky chamber due to damaged OroboPOS-Holder

O2k-chamber disassembly

- After siphoning off any medium from the O2k-chamber, remove the OroboPOS-Connector and O2k-Chamber Holder from the O2k.

- Insert your finger (with gloves on) into the chamber and then gently pull the glass chamber up.

- Problem: Glass chamber stuck in the O2k, and the O2k-Chamber cannot be removed. It remains stuck even after washing with water.

- This may be caused by spilled medium acting as an adhesive between glass chamber and copper block. Wash with plenty of warm water and try to remove the chamber while the O2k is switched on and heated up to 37 °C. Then GENTLY screw in the sensor holder (not the sensor connector) to push the glass chamber upwards (as performed during the O2k-chamber assembly).

- If this does not work, increase the temperature to 40 °C (or slightly higher) for washing and continue with removing attempts.

Video support for O2k-chamber service

- Instructions on insertion of the O2k-Chamber and volume calibration: Chamber service

Keywords

- »Bioblast links: Chamber volume - >>>>>>> - Click on [Expand] or [Collapse] - >>>>>>>

- » Volume

- Units: Liter [L]; 1 L = 1 dm3 = 10-3 m3; 1 mL = 1 cm3; 1 µL = 1 mm3

- » Volume

- On chamber volume

- Components of the experimental O2k-chambers

- » Stirrer-Bar\white PVDF\15x6 mm

- » Stirrer-Bar sV\white PVDF\11.5x6.2 mm

- » Stopper\black PEEK\conical Shaft\central Port

- » Stopper sV\black PEEK\conical Shaft\central Port

- » O-ring\Viton\12.5x1 mm

- » O-ring sV\Viton\9.5x1 mm

- » Volume-Calibration Ring

- » Volume-Calibration Ring sV

- » Stopper-Spacer

- » Cover-Slip\black

- » O2k-Chamber Holder

- » O2k-Chamber Holder sV

- » OroboPOS-Holder

- » OroboPOS-Holder sV

- Maintencance

MitoPedia O2k and high-resolution respirometry: O2k hardware, O2k-Open Support, O2k-Respirometry, O2k-FluoRespirometry